What are the different types of overhead crane? Which type of overhead crane is for your application? Single Girder Overhead Crane,JIB Crane, Double Girder Overhead Crane,Metallurgical Overhead Crane,Overhead Grab Crane,Top running Overhead crane,Under running (under hung) Overhead crane. Each type has its own unique benefits and drawbacks.

Single Girder Overhead Crane

Single girder Overhead cranes consist of a single bridge beam attached to the runways and are the proven solution for many material handling challenges. Single girder Overhead cranes can be provided with manual chain hoists, electric chain hoists, or electric wire rope hoists for maximum flexibility in your work area and are highly customizable.

Single Girder Overhead Crane Uses

Single girder overhead crane is commonly employed for light duty or moderate services in workshops, warehouses, storage yards, etc. Paper,Recycling and Bulk Handling,Aviation,Steel Production,Steel Handling,Cement,Glass,Machinery and Equipment,Concrete,Bricks

Single Girder Overhead Crane Cost

The Single girder overhead crane is cheap, but also don’t have as much lifting power.

Double Girder Overhead Crane

A double girder overhead crane configuration is made up of two bridge girders, two end trucks, and a trolley hoist assembly. The trolley hoist travels on top of rails that are mounted to the top of the bridge girders.

Due to their exceptionally reliable and safe design, double girder cranes are widely used in:

Application of Double Girder Overhead Crane

on open areas of large warehouses, large cargo terminals,

in the construction and installation of large-scale facilities,

in foundries of metallurgical enterprises,

in the assembly shops of factories producing large-sized equipment and machine tools,

in workshops and warehouses of large enterprises in the food, chemical and pharmaceutical industries, incl. in fire and explosion hazardous industries.

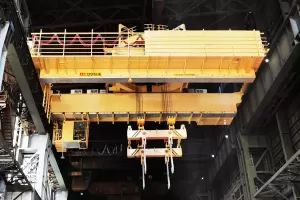

Metallurgical Overhead Crane

A metallurgical overhead crane is a crane that is used to move heavy metal objects, typically in a foundry or Steel Mills environment.

Ladle metallurgical overhead (bridge) cranes are divided into transporting, Ladle Crane, charging and casting cranes. The transporting metallurgical foundry bridge crane.

metallurgical cranes are built to withstand the high heat and heavy loads often found in these settings. Metallurgical Overhead Cranes typically have a higher lifting capacity than Standard Overhead Cranes, and they may also be equipped with special features such as magnetic lifting devices to make handling metal objects easier. and are equipped with special features such as fire-resistant coating and explosion-proof motors.

Metallurgical Overhead Crane Uses

Metallurgy overhead crane is used for metallurgy industry. It is fitted with special spreaders such as hook, clamp, grab, magnetic beam, disc, etc.

Iron and steel metallurgy, electricity, water, aerospace, shipbuilding, automobiles, coal, petrochemicals

Overhead Grab Crane

Grab overhead crane is commonly employed for handling bulk materials. It comes in two basic configurations, single girder and double girder. The crane helps increase your factory production and ensure a safe operation.

Overhead Grab Crane Uses

Girder Grab Crane is developed and evolved from double girder bridge crane, suitable for metallurgy, steel mills, brewing, building materials, chemicals, coal and other industries or outdoors across fixed span, engaged in minerals, steel scrap, wine tank, slag, coke, coal, sand and other parts or granular materials lifting and handling work.

Top running Overhead crane

Top-running cranes are the ideal solution for industrial buildings with limited headroom. A top running overhead crane has a fixed rail or track system installed on the top of each runway beam allowing the end trucks to carry the bridge and hoist along the top of the runway system. Top running cranes can be configured in a single girder or double girder bridge design.

Top running Overhead crane Uses

Top running overhead crane has often used lifting hoist equipment for heavy or small service. It is widely applied in the manufacturing, machine shops, fabrication, assembly line, maintenance, and warehousing facilities, etc.

Under running Overhead crane

An under running crane, or commonly referred to as an “underhung” crane, uses wheels that are supported by the bottom flange of the runway beam to move the bridge up and down the runway. Under running cranes are most commonly configured in a single girder design for lighter service and lower-capacity applications.

Under running Overhead crane System

It uses together with CD1 model MD1 model electric hoist as a complete set, it is a light duty crane with a capacity 0.5 ton ~ 10ton. The span is 5-40m. Working duty is A3~A5, working temperature is -25-40℃.

Under running Overhead crane Uses

Under Running Single Girder Overhead Crane is widely used in plants warehouse,steel plant,steel yard, material stocks etc to lift goods.