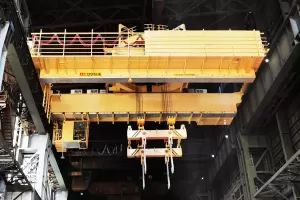

Overhead crane with electromagnetic beam is a specialized crane for lifting and moving steel products, steel plates and steel pipes. This crane is constituted by girder, traveling mechanisms, lifting trolley, electric parts and electromagnet spreader.

This overhead crane's electromagnetic suction force can last for 10 minutes after it is powered off. The shape of the electromagnet spreader can be customized based on the materials being lifted. It can be round-type megnetic lifting or square-type megnetic lifting .

If you're in the market for an overhead crane, you may have heard about models that come with an electromagnetic beam. This type of crane is becoming increasingly popular, due to its many advantages over traditional models. But what exactly is an electromagnetic beam, and what do you need to know before buying one?

Type of Hanging Beam Magnetic Overhead Crane

There are two types of electromagnetic spreader: electromagneticchuck and the electromagnetic beam. There are two types of electromagnetic beam: the non-rotating beam, which is vertical or parallel to the main girder, and the rotating beam (Upper beam)

Overhead Crane with Electromagnetic Beam application

This Overhead Crane with Electromagnetic Beam has two hooks and the ability to lift and transfer long steel plate or scrap materials, iron or steel blocks in steel plants, harbors, and warehouses and so on.

Features

- Three entrances to the operator's cabin: end, side and top entrances;

- The rotating part of the hook must be locked by screws when electromagnets working;

- Lifting capacity includes the weight of electromagnets beam spreader, and weight of the whole crane does not include the weight of electromagnets and its components;

- Box girder is welded in high strength by robots;

- Wheels, winding drums, gears and couplings are manufactured by CNC machine with the best quality;

- Bridge truck has a centralized lubricating system;

- International and Chinese famous brands of motors such as ABB, Siemens or Wuxi NGP will be used as per customer's requirement;

- Electrical parts made by Siemens, Schneider, Mitsubishi, CHINT, DELIXI.

- Independent control system: wireless remote control or operator's cab console control;

- Be equipped with hoisting overload protection device;

- Polyurethane buffer be equipped at both long traveling and cross traveling mechanisms;

- Long travel and cross travel with limit switch;