The truss gantry cranes has latticed structure with a small windward area, light weight, good lifting ability and so on. This truss gantry crane is an ideal lifting equipment employed in the warehouse, freight yard, terminals and other places.

Introduction of truss gantry cranes

Truss cranes are a type of bridge crane that are used to move large objects. They are made up of a series of interconnected metal beams that form a truss. This allows the crane to support large loads without bending.

The truss gantry cranes is used in conjunction with CD1 electric hoists, MD1 electric hoists. It is a small and medium-sized truss gantry cranes running on rails. It is suitable for a lifting capacity of 3-20 tons and a suitable span of 12-30 meters. Working environment -20°C ~ +40°C.

The truss gantry crane is a general purpose crane, which is mostly used for loading and unloading or grabbing materials in open spaces and warehouses. The truss gantry crane has two types of ground control and indoor control.

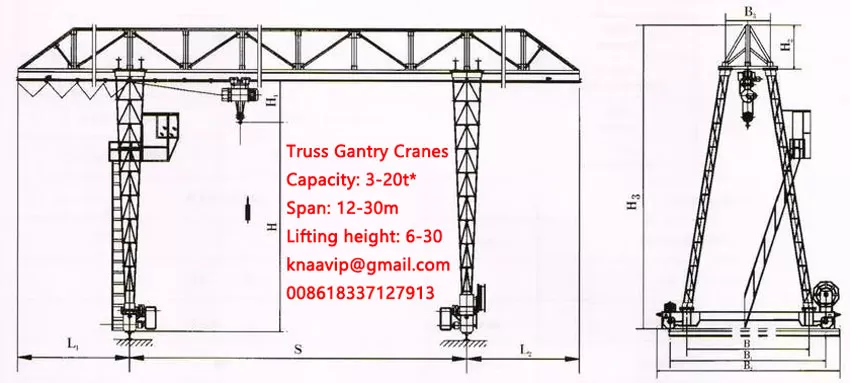

Truss Gantry Cranes drawings

Truss Gantry Cranes video

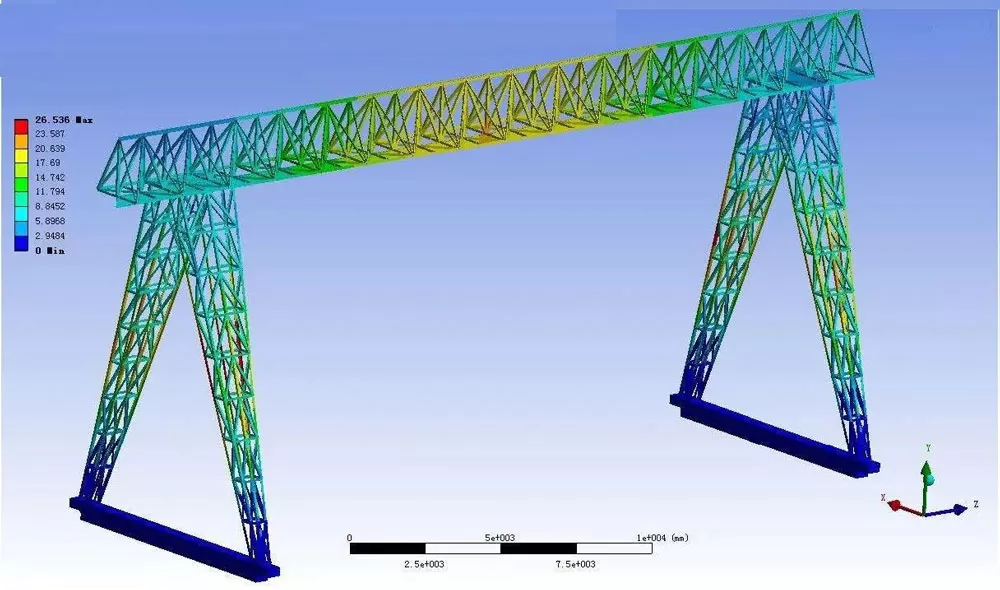

The stress distribution diagram of the main structure of the truss cranes

What are the advantages of truss cranes?

- Increased Efficiency - Truss Crane can significantly increase the efficiency of your operation. This is because they are much faster and easier to set up than traditional cranes.

- Increased Capacity - Truss Crane can lift more weight than a traditional crane. This makes them ideal for lifting heavy loads.

- Increased Stability - Truss Crane is much more stable than a traditional crane. This makes them ideal for lifting heavy loads in windy or unstable environments.

- Increased Safety - Truss Crane is much safer than a traditional Gantry crane. This is because they are less likely to tip over.

- If you are looking for a way to increase the efficiency, capacity, stability, and safety of your operation, then a Truss Crane is the perfect solution.

Difference between box girder crane and truss girder crane?

Each type of gantry crane has its own strengths and weaknesses. The single box girder crane is the lightest and simplest, but has the least carrying capacity. The Double box girder crane is the strongest and most rigid, but is also the heaviest. The truss crane is the most versatile, with a large carrying capacity and good maneuverability.How do you install a truss crane?

Installing a truss crane is not a difficult process, but it is important to follow the correct steps to ensure that the truss crane is properly secured and safe to use. The first step is to determine the location where the truss crane will be installed. The truss crane must be installed in a level area that is clear of obstacles and has enough room for the truss crane to move around.

Once the location is determined, the next step is to measure and mark the area where the base of the crane will be installed. The base should be installed in a square or rectangle shape, and the measurements should be accurate to ensure that the crane is properly secured. Once the base is marked, the next step is to install the base.

The base can be installed with either nails or screws, but it is important that it is installed securely. Once the base is in place, the next step is to install the columns. The columns should be installed in the corners of the base, and they should be installed at the same height.

Once the columns are in place, the next step is to install the trusses. The trusses should be installed in a triangular shape, and they should be evenly spaced. Once the trusses are in place, the next step is to install the beams. The beams should be installed in the middle of the trusses, and they should be installed at the same height.

Once the beams are in place, the next step is to install the hoist. The hoist should be installed in the center of the beams, and it should be installed at the same height. Once the hoist is in place, the next step is to install the trolley. The trolley should be installed on the hoist, and it should be installed at the same height.