Jib cranes have proven to be a staple in many industrial and manufacturing operations. These types of cranes typically consist of a horizontal jib or arm that extends from a vertical column or pillar mounted on a stationary base, making them ideal for handling materials in a limited space. Jib cranes come in different designs and configurations, with different load capacities and boom lengths to meet the needs of various industrial applications. In this post, we will explore some of the things that industrial buyers and plant managers should consider when purchasing jib cranes for their operations.

Load Capacity

Before purchasing a jib crane, it is essential to determine the weight of the materials to be moved or lifted. Jib cranes come in various load capacities, from light-duty to heavy-duty models. Plant managers need to ensure that the crane's load capacity matches the weight of the materials it will be handling. If too heavy, it may lead to safety hazards or even crane failure.

Boom Length

Another crucial factor in selecting a jib crane is the boom length, which refers to the horizontal arm's maximum reach. The boom length required for a given application is determined by the distance between the load's pick-up and drop-off points. It is crucial to consider the space available in the plant and the height of the ceiling when deciding on the boom length.

Crane Type

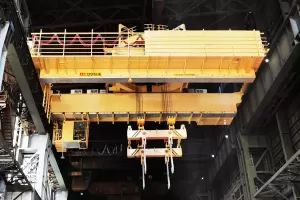

There are different types of jib cranes, including motorized jib cranes, electric jib cranes, and manual jib cranes. Motorized jib cranes are best for heavy-duty operations, while electric jib cranes are more suitable for light-duty applications. Manual jib cranes, on the other hand, are ideal for lighter loads and more moderate use. Plant managers will need to select a crane that matches the needs of their operations based on the type of materials that need to be moved and the frequency of use.

Jib Crane Accessories

To optimize the jib crane's performance, plant managers will need to consider accessories such as jib crane hoists, jib crane motors, or jib crane booms. Depending on the applications, some accessories may or may not be necessary. For instance, a jib crane motor may not be required for lighter loads or manual applications. However, jib crane hoists can make it easier and safer to lift and lower heavy loads.

Conclusion

Industrial buyers and plant managers should take into account the load capacity, boom length, type, and accessories when purchasing a jib crane. Jib cranes are an important investment for the plant and will significantly impact operational efficiency and safety. By selecting a proper jib crane, plant managers can improve productivity, reduce material damage, and ensure worker safety.